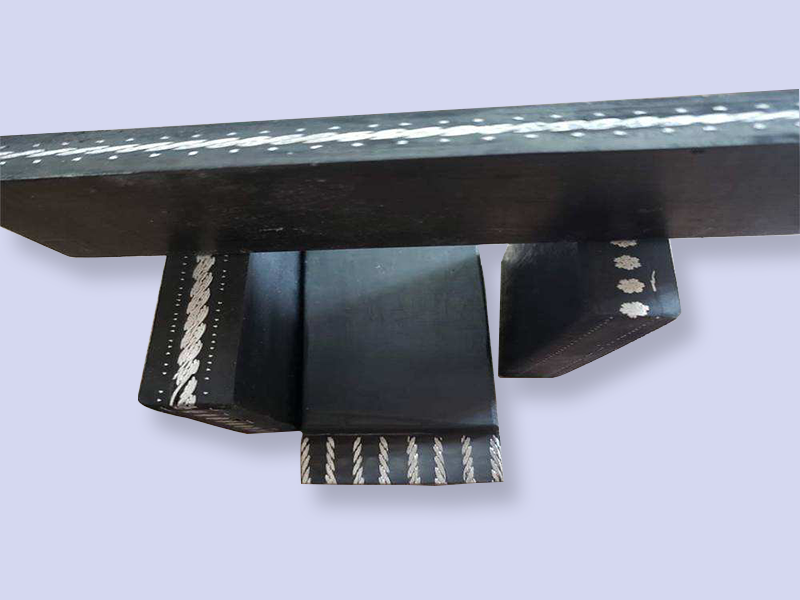

钢丝绳芯输送带

钢丝绳芯输送带

钢丝绳芯输送带

- 产品详情

用 途 /Purpose

广泛用于煤炭、矿山、港口、冶金、电力、化工等领域长距离、大运作、高速度输送物料的行业及场所。

It is widely used in industries and places that transport materials with long distance, large operation and high speed in coal, mining, port, metallurgy, electric power, chemical industry and other fields.

执行标准 /Executive standard

我公司生产的钢丝绳芯输送带除执行GB/T9770-2013外,还可以执行煤矿井下用阻燃钢丝绳输送带MT668-2008标准、德国DIN22131标准、日本JISK6369标准、澳大利亚

AS1333、南非SAN1173标准等。In addition to GB / t97702013, the steel wire rope core conveyor belt produced by our company can also implement themt6682008 standard of flame retardant steel wire rope conveyor belt for underground coal mine, German din22131standard, Japanese jisk6369 standard, Australian as1333 standard, South African san1173 standard, etc.

特 点 /Characteristic

◆本产品具有防霉、防蛀、防老化、耐热性好、抗撕裂强度高以及使用强度高,安全系数高。

This product is mould proof, moth proof, anti-aging, good heat resistance, high tear strength, high use strength and highsafety factor.

◆拉伸强度大,抗冲击性好,耐曲绕性好,使用生长小,拉紧形成距离短,带体柔软,动态性能良,直线运行性能好。

High tensile strength, good impact resistance, good bending resistance, small growth, short tension forming distance, soft5belt body, good dynamic performance and good linear operation performance.

◆钢丝绳与橡胶粘着性能好:采用镀锌全开放式结构钢丝绳子与橡胶有良好的粘合型和渗透性,透气性试验指标达到国家先进水平;钢丝绳张力均匀、间距均匀,张力一致运

行平稳,不易跑偏,带体整体性好,钢丝绳不拔脱,不易掉块,使用寿命长。

Good adhesion between steel wire rope and rubber: galvanized fully open structure is adopted, steel wire rope and rubber5have good adhesion and permeability, and the air permeability test index has reached the national advanced level; The5tension of the steel wire rope is uniform, the spacing is uniform, the tension is consistent, the operation is stable, it is not5easy to deviate, the belt body has good integrity, the steel wire rope is not pulled out, it is not easy to fall off, and the service life is long.

钢丝绳芯输送带规格及技术参数 /Specification and technical parameters of steel wire rope core conveyor belt

带型号 Belt mode | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6000 | 7000 | 7500 | |

| 最小拉断强度(N/mm) | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6000 | 7000 | 7500 | |

| 钢丝绳**直径mm | 3 | 3 | 3.5 | 4 | 4.5 | 5 | 5 | 5.6 | 6 | 5.6 | 7.2 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 12.8 | 13.5 | 15 | |

| 钢丝绳最小拉断力kN | 7.6 | 7 | 8.9 | 12.9 | 16.1 | 20.6 | 20.6 | 25.5 | 25.5 | 26.2 | 40 | 39.6 | 50.5 | 56 | 63.5 | 76.3 | 91 | 98.2 | 130.4 | 142.4 | 166.7 | |

| 钢丝绳间距mm | 14 | 10 | 10 | 12 | 12 | 14 | 12 | 13.5 | 12 | 11 | 15 | 13.5 | 15 | 15 | 15 | 16 | 17 | 17 | 19.5 | 19.5 | 21 | |

| 推荐上覆盖层厚度mm | 5.0 | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 | 10.0 | 10.0 | 10.0 | |

| 推荐下覆盖层厚度mm | 5.0 | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 | 10.0 | 10.0 | 10.0 | |

| 带体厚度mm | 13.0 | 13.0 | 13.5 | 16.0 | 16.5 | 17.0 | 17.0 | 17.6 | 22.0 | 21.6 | 23.2 | 23.2 | 24.1 | 24.6 | 24.9 | 25.7 | 27.9 | 29.3 | 32.8 | 33.5 | 35 | |

| 带参考单位重量kg/m² | 16.9 | 17.7 | 18.4 | 21.6 | 23.3 | 24.3 | 25.1 | 27.3 | 32.2 | 32.4 | 35.5 | 36.5 | 48.8 | 40.4 | 43.1 | 45.4 | 50.3 | 53.3 | 65.1 | 68.9 | 63.1 | |

| 带宽㎜ | 极限偏差㎜ | 钢丝绳根数 | ||||||||||||||||||||

| 500 | +10/-5 | 33 | 45 | 45 | 39 | 39 | 34 | 39 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| 650 | +10/-7 | 44 | 60 | 60 | 51 | 51 | 45 | 51 | 46 | 52 | 56 | 41 | 46 | 41 | 41 | 41 | 39 | 36 | N/A | N/A | N/A | N/A |

| 800 | +10/-8 | 54 | 75 | 75 | 63 | 63 | 55 | 63 | 57 | 63 | 69 | 50 | 57 | 50 | 50 | 51 | 48 | 45 | 45 | N/A | N/A | N/A |

| 1000 | ±10 | 68 | 95 | 95 | 79 | 79 | 68 | 79 | 71 | 79 | 86 | 64 | 71 | 64 | 64 | 64 | 59 | 55 | 55 | N/A | N/A | N/A |

| 1200 | ±10 | 83 | 113 | 113 | 94 | 94 | 94 | 94 | 85 | 94 | 104 | 76 | 85 | 76 | 77 | 77 | 71 | 66 | 66 | 58 | 59 | 54 |

| 1400 | ±12 | 96 | 133 | 133 | 111 | 111 | 94 | 111 | 100 | 111 | 122 | 89 | 99 | 89 | 90 | 90 | 84 | 78 | 78 | 68 | 69 | 54 |

| 1600 | ±12 | 111 | 151 | 151 | 126 | 126 | 111 | 126 | 114 | 126 | 140 | 101 | 114 | 101 | 104 | 104 | 96 | 90 | 90 | 78 | 80 | 73 |

| 1800 | ±14 | 125 | 171 | 171 | 143 | 143 | 125 | 143 | 129 | 143 | 159 | 114 | 128 | 114 | 117 | 117 | 109 | 102 | 102 | 89 | 90 | 83 |

| 2000 | ±14 | 139 | 191 | 191 | 159 | 159 | 139 | 159 | 144 | 159 | 177 | 128 | 143 | 128 | 130 | 130 | 121 | 113 | 113 | 99 | 100 | 92 |

| 2200 | ±15 | 153 | 211 | 211 | 176 | 176 | 154 | 176 | 159 | 176 | 195 | 141 | 158 | 141 | 144 | 144 | 134 | 125 | 125 | 109 | 110 | 102 |

| 2400 | ±15 | 167 | 231 | 231 | 193 | 193 | 168 | 193 | 174 | 193 | 213 | 155 | 173 | 155 | 157 | 157 | 146 | 137 | 137 | 119 | 119 | 110 |

注: 1、N/A由于成槽性的原因而不适用; 2、由于配方比重不同,输送带参考单位重量和实际会有差异。 | ||||||||||||||||||||||

覆盖胶性能等级 /Performance grade of covering glue

GB/T9770-2013标准中覆盖胶性能等级 DIN22131标准中覆盖胶性能等级

性能类型 Performance type | 拉伸强度.MPa≥ Tensile strength MPa≥ | 拉断伸长率.% ≥ Elongation at break.% ≥ | 磨耗量.㎜³≤ Abrasion ㎜ ³ ≤ | 性能类型 Performance type | 拉伸强度.MPa≥ Tensile strength MPa≥ | 拉断伸长率.% ≥ Elongation at break.% ≥ | 磨耗量.㎜³≤ Abrasion ㎜ ³ ≤ | |

| H | 24 | 450 | 120 | W | 18 | 400 | 90 | |

| D | 18 | 400 | 100 | X | 25 | 450 | 120 | |

| L | 15 | 350 | 200 | Y | 20 | 400 | 150 | |

| 注:H用于输送对带子有强烈损害的尖利磨损性物料;D用于输送高磨损性物料;L用于输送中度磨损物料。 | K* | 20 | 400 | 200 | ||||

| 注:*适用于符合DIN22103的一般阻燃输送带,其覆盖胶符合DIN22104的要求。 | ||||||||

钢丝绳芯输送带推荐使用的输送机最小辊筒直径/

The minimum roller diameter of the conveyor recommended for wire rope core conveyor belt

胶带型号 Tape model | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST500 | ST5400 |

| 最小辊筒直径㎜ | 500 | 500 | 630 | 800 | 1000 | 1000 | 1250 | 1400 | 1600 | 1600 | 1800 | 1800 | 1800 |